-

Call us

Need to know what we have in stock? 01363 775555

-

Special offers

Competitive prices on popular items

-

Open 7 days a week

Whenever you need us

-

Expert Advice

Our knowledgeable staff are here to help

CMC Eakers

CMC Eakers is your local DIY store in Crediton, serving the Exeter area and beyond. We offer a wide range of tools materials and accessories for professional tradespeople, homeowners and DIY enthusiasts.

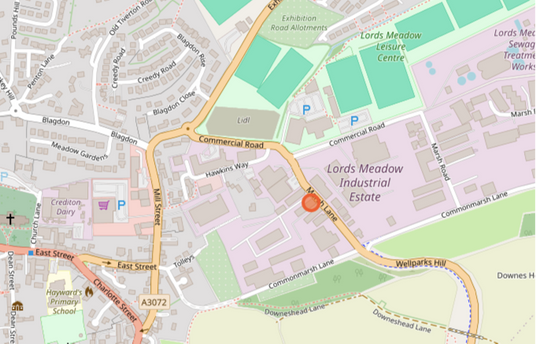

Find us at..

CMC Eakers

Lords Meadow Industrial Estate

Marsh Lane

Crediton

Devon

EX17 1ES

01363 775555

Testimonials

Good general purpose store for DIY needs. Paints, varnishes, sealants, plumbing supplies, tools, wood and glass. Just had a revamp and reorganisation and now very smart inside. Staff very helpfull.

Exciting times as it goes into new ownership but with the same dedicated staff

Fantastic customer service, I needed a specific size length of wood, they didn't have an exact match, so cut a piece for me. Good old fashioned hardware store with an excellent range of stock. Thanks so much for your help

stay updated

Sign up for CMC Eakers updates straight to your inbox